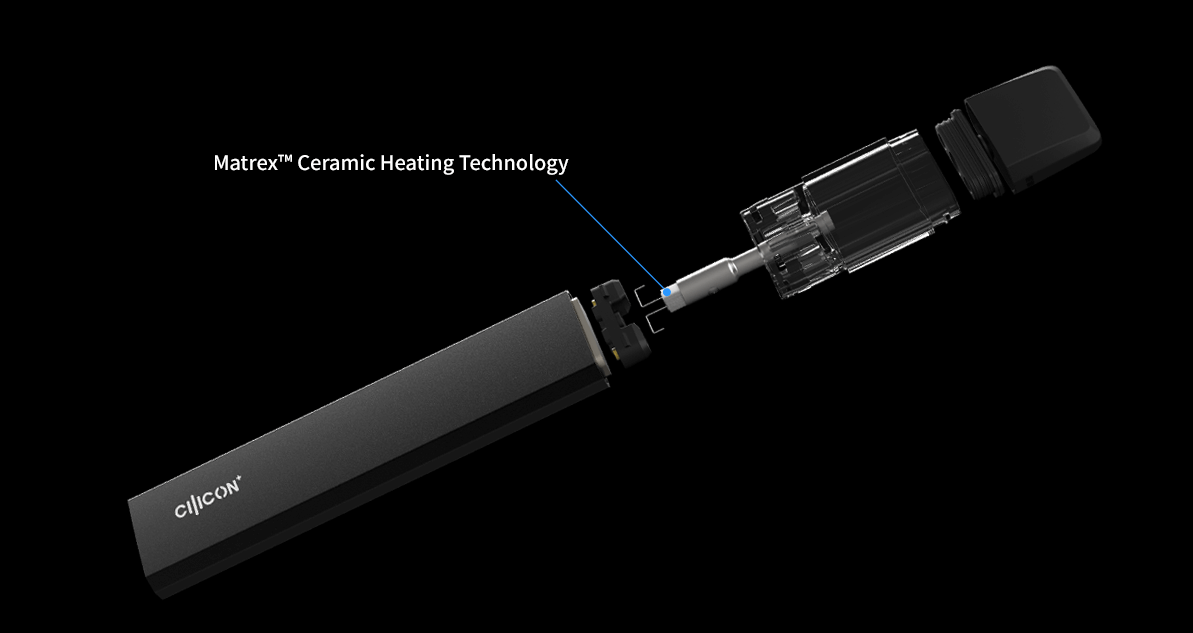

Formatrix™ Technology is the newest development created by the Cilicon design department to meet the changing needs of cannabis vape consumers and producers. The Formatrix™ ceramic heating element, used in all new Cilicon atomization devices, sets a new standard in a number of the most critical categories for industry production efficiency and consumer satisfaction. Ceramic heating elements have grown in popularity within the industry over the last decade, and the Formatrix™ element redefines the possibilities of the consumer vaping experience. The Formatrix™ element uses Cilicon’s specially formulated Formatrix™ Ceramic to create a vaping experience that is efficient, smooth and takes advantage of the natural taste and smell of cannabis that consumers love. The new element design is also created with production efficiency in mind, with a reduced size and reduced material usage, among other improvements. With Formatrix™ Ceramic Heating Technology, Cilicon demonstrates a deep investment in believing that ceramic heating technology is here to stay.

The Advantages of Ceramic

Ceramic heating elements have several advantages over other elements, such as elements that use a cotton wick wrapped around a metal coil. All ceramic heating elements benefit from reducing the potential for overburning or dry hits compared to a cotton wick. All ceramic heating elements do a better job of preserving the natural taste of cannabis oil. All ceramic elements reduce health concerns by reducing the inhalation of heavy metals or other materials. Moreover, ceramic has high strength and the ability to withstand extreme temperatures, leading to increased efficiency in production and increased durability during use.

Formatrix™: Pushing Forward Heating Element Technology

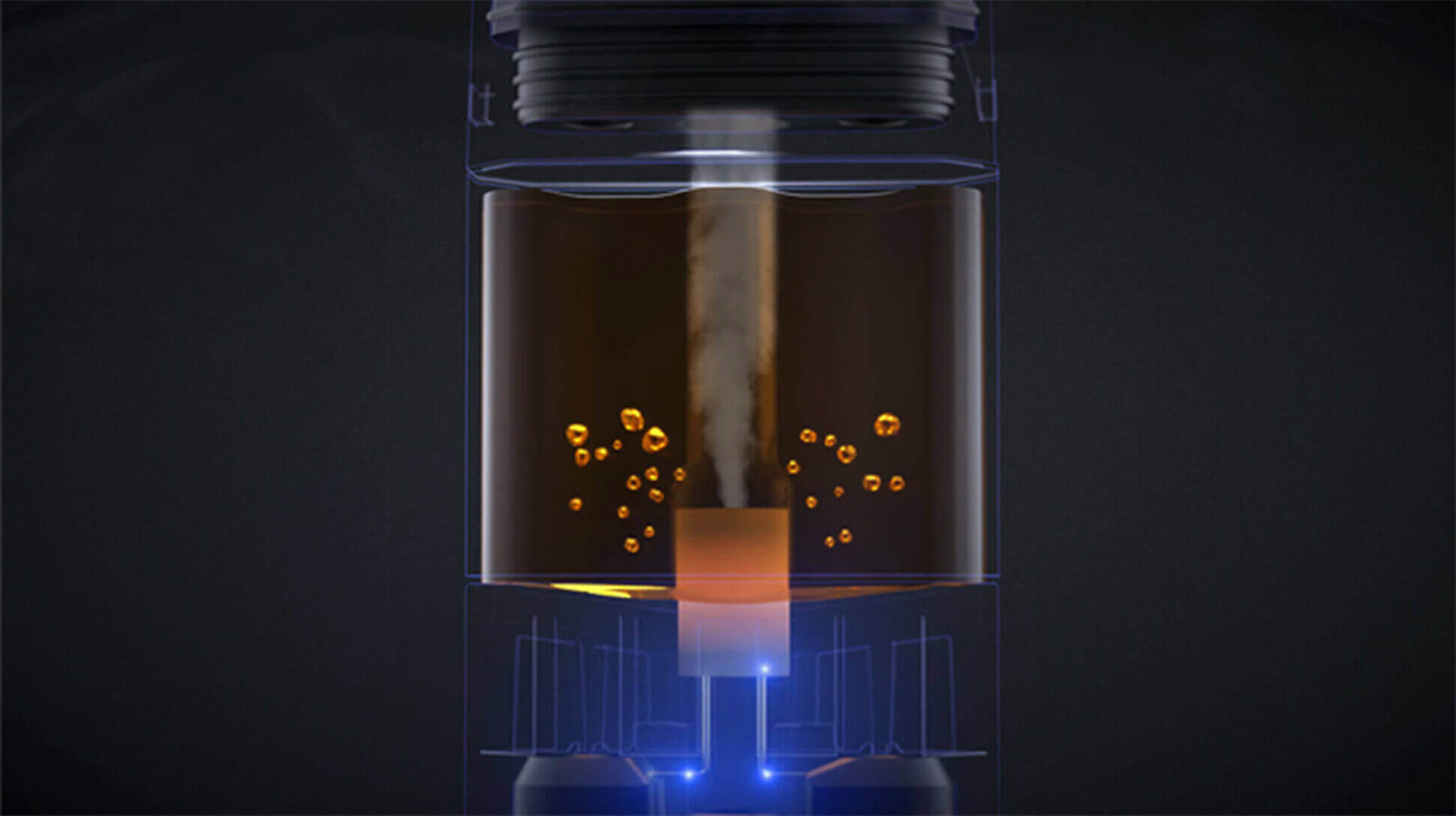

However, Formatrix™ Ceramic Heating Technology is unlike any ceramic heating element that came before it. Cilicon’s Formatrix™ Ceramic has been developed to create a ceramic material that meets consumer and business needs. These improvements are accomplished with patented design innovations developed over years of experience and investment. Formatrix™ Ceramic Technology is designed using a proprietary formula for minimizing flow resistance of atomization liquid across the ceramic surface of the element. Cilicon designers have utilized the full extent of scientific knowledge of ceramic to bring a new level of precision to the heating element design. This process results in an even dispersion of surface tension between the element and the liquid, with several benefits for the end consumer. First of all, the even dispersion of surface tension maximizes the volume of each puff, leading to bold and full hits.

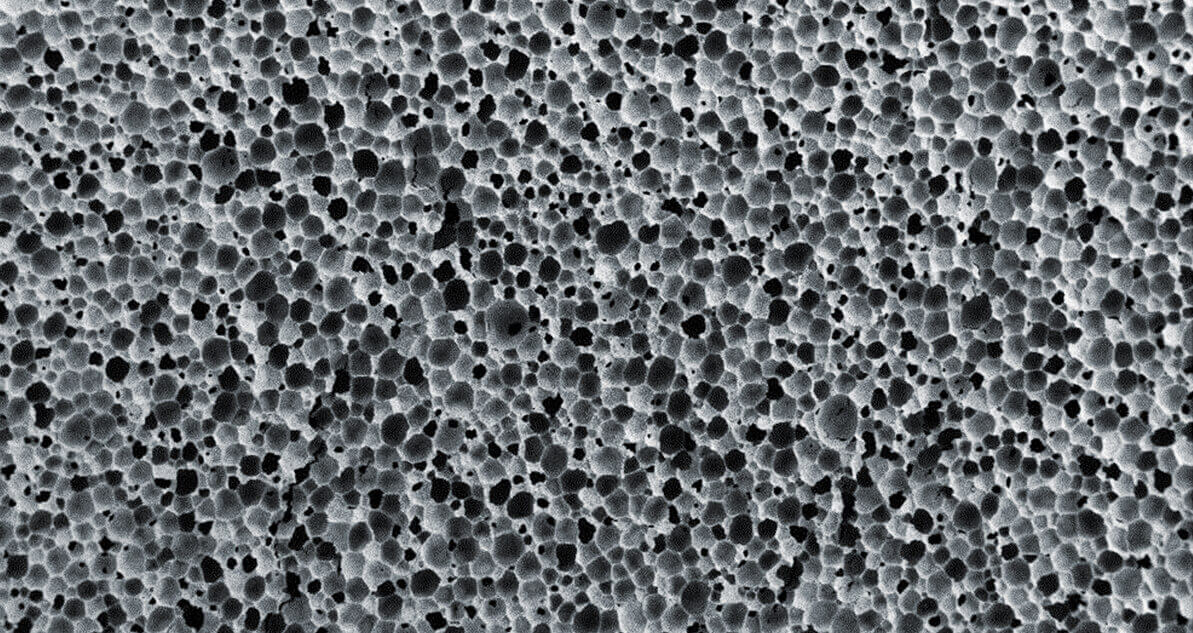

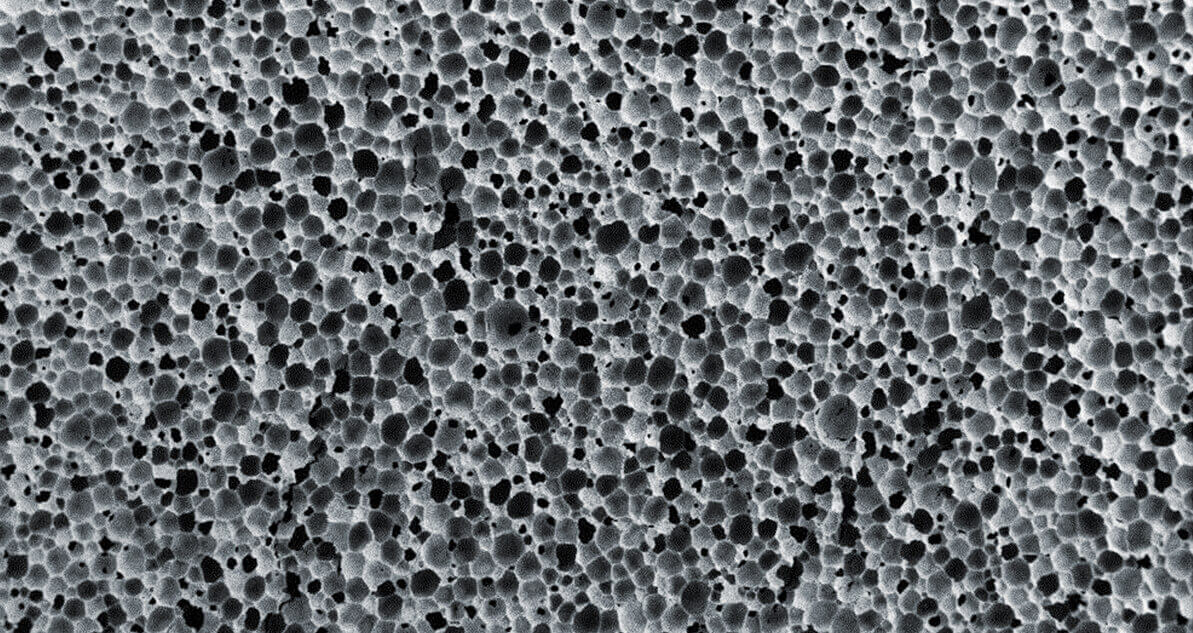

Second, the Formatrix™ Ceramic included in the device is designed with optimized porosity and pore size while also increasing the strength, leading to several benefits. The higher the porosity, the lower the flow resistance of the atomized liquid, and the ceramic surface tension between the porous material and the atomized liquid is evenly dispersed during the heating process.

Its relatively small size is another improvement that the Formatrix™ ceramic heating element offers over existing ceramic elements. The Cilicon design team has utilized the ability of ceramic to maintain its flow properties at a reduced size to improve both consumer experience and production efficiency. Formatrix™ Technology allows the same volume of oil per second to be absorbed and vaporized by the ceramic, resulting in a higher purity of terpene content in the vapor.

Formatrix™ and the Production Chain

The Formatrix™ ceramic heating element offers several distinct advantages for the production chain. All Formatrix™ elements are certified with over 2000 tests for safety and functionality, ensuring the use of the purest and least defective materials. The core can withstand sintering at 1200°C temperatures, adding increased maneuverability in the production process. Licensed distributors can have the confidence that Cilicon has taken every step to streamline the process. The product goes from the manufacturing factory to the filling operation and finally to the consumer.

The porosity of the Formatrix™ Ceramic has been increased by 20%, while the toughness has also increased. An increase in porosity improves consumer satisfaction by increasing the density of each puff. The element is also designed to have evenly dispersed oil across the ceramic. The even dispersion of oil flow across the ceramic leads to perfect uniformity for each hit, with a steady stream of dense vapor over the entire inhalation period. The combined result of this improvement is a vaping experience that meets a growing consumer preference for control and efficiency.

While ceramic elements are generally safer than cotton wick coils, ceramic elements do emit a small amount of ceramic powder. This amount is reduced with the use of Formatrix™ Ceramic. Moreover, when coupled with a heating wire made of medical grade stainless steel (316L), the increased toughness of Formatrix™ Ceramic leads to a reduction in powder drop rate or rate of ceramic particles that come off the element during use. The use of 316L stainless steel also produces a relatively regular TCR curve, thus allowing future devices to be compatible with temperature control technology by monitoring changes in the TCR curve, which is the key factor in achieving temperature control functionality.

Cilicon: Providing Consumer Value

From the consumer’s perspective, the result is a more efficient product that provides a more pleasant experience and a product that can be sold at a cheaper price point. Consumers ultimately enjoy Cilicon’s innovative design efficiency across the whole production chain as a product that achieves better performance than other devices on the market while maintaining a fiercely competitive price point. Formatrix™ Ceramic Heating Technology allows consumers to enjoy the convenient and discrete use of their atomization devices while maximizing their enjoyment of the taste and aroma of terpenes. Consumers know that they will get a hit that is packed with flavor and exactly dispersed as it was on the last. The ability of Formatrix™ Ceramic Heating Technology to provide value to consumers in these ways is the most significant manifestation of its potential to create new standards in the cannabis atomization industry.