What’s Oil IsolationTM Technology

Cilicon’s proprietary Oil IsolationTM Technology is one of the latest advances from the Cilicon design team that addresses pressing issues in the cannabis vaping industry and brings value to businesses and consumers. Cilicon has identified oil leakage that occurs through the inlets in the oil tank as a prevalent industry challenge. Oil IsolationTM Technology addresses this design challenge with the result of reducing leakage by over 99%. The Oil IsolationTM Technology solves the cannabis oil leaking problem from the inlet during the oil-filling process and beyond, resulting in increased production efficiency, benefits for distributors, and value for end-users.

Instead of allowing leaking from the inlets, the Oil IsolationTM Technology keeps the oil separate from the inlets while allowing air to flow through the inlets and the rest of the device. Leaking is minimized while performance is optimized. Moreover, the decrease in leaking improves the production and post-production processes in several ways, decreasing wastage while improving processing times and efficiency. Silicon’s Oil IsolationTM Technology leaves a lasting impact on the industry by demonstrating to distributors and consumers that they do not have to experience the problem of oil leakage.

Design Inspiration Stemming from Market Insights

The oil core separation system is inspired by several design and market issues prevalent across the vaping industry. First of all, the Oil IsolationTM Technology introduces several innovations which improve efficiency during the filling process. Traditional oil tanks have no method of preventing leakage from the tank’s inlets before the tank has been capped. As a result, each tank must be capped within 3-5 minutes of filling, or the issue of oil leakage will probably occur. The maximum number of devices produced in each production cycle is limited, and overall efficiency suffers.

Moreover, traditional oil tanks also create the opportunity for leakage after a device has been capped, which can impact the filling process and distribution. The other tanks that currently exist on the market can leak both during the filling process and distribution. As a result, consumers purchase a product that may already experience performance and appearance downgrades. Finally, traditional oil tanks create the potential for oil leakage during consumer use conditions. Leakage is especially likely to occur during extreme weather conditions or when excessive air intake is pushed through the oil tank. Oil leakage reduces the efficiency and longevity of a device, ultimately reducing consumer satisfaction.

The Technical Principles of Oil IsolationTM Technology

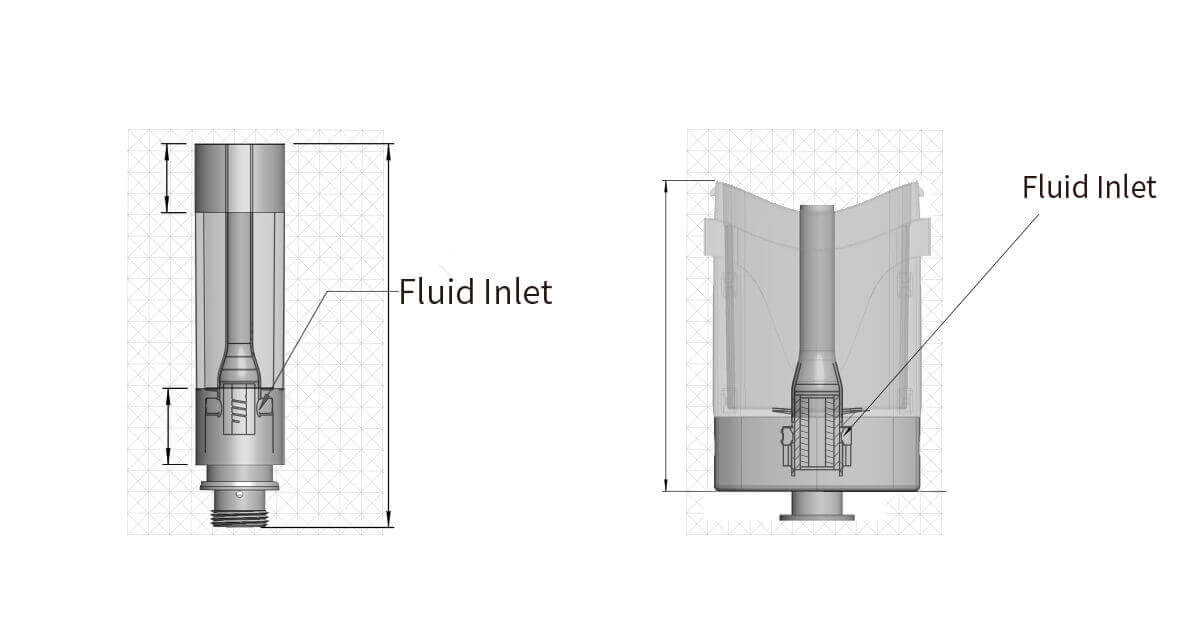

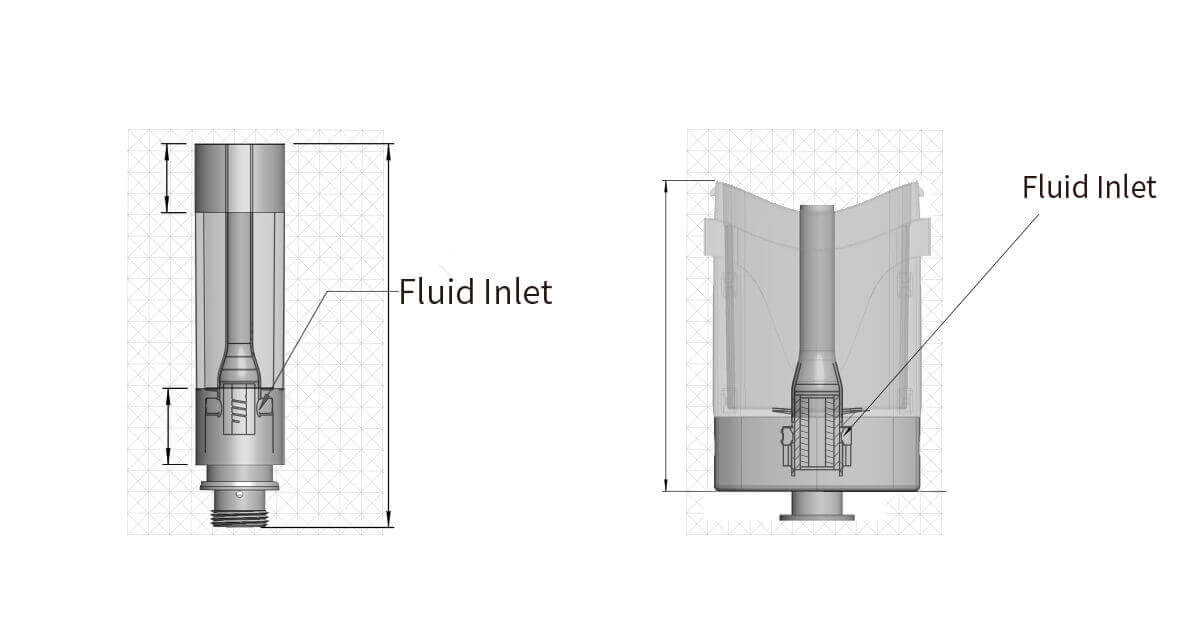

Cilicon’s Oil IsolationTM Technology eliminates the industry’s oil leakage issue for good. The technology has been engineered to restructure the oil tank design by relocating the oil inlet at the bottom of the chamber and separating it from the cap. Furthermore, the Oil IsolationTM Technology has detached the oil tank within the chamber by enabling it to be pushed further down to increase the distance between the open-end side of the chamber against the inlet. Once the oil tank is pushed further down, the bottom proportion of it is isolated by the silicon cap underneath. Such approaches are specially designed to avoid oil leakage from the inlet during the oil filling process.

Finally, once the filling process is accomplished, the mouthpiece can be re-assembled, and the oil tank can be raised to the original position by pushing the metal holder upward against the silicon cap. Cilicon cares to solve our clients’ pain points by incorporating our R&D team to ensure the oil filling process can be very efficient and eliminate the overall leakage possibility by 99%. The Oil IsolationTM Technology is also tested to reduce the influx of airflow within the oil tank. As the amount of airflow is controlled, the vaping experience of the end-users can become pleasant and satisfactory.

The Advantages for Cilicon Partners

The Oil IsolationTM Technology provides several clear advantages for businesses purchasing and distributing Cilicon products. The isolation of oil from the inlets in the tank removes the need for technicians to cap immediately. Therefore, batches can be filled in much larger sizes before capping occurs, increasing efficiency and reducing labor costs. Moreover, reducing leakage in the device across various conditions minimizes the potential for inventory depreciation. With leakage minimized throughout the entire supply chain, businesses can establish a high level of consumer confidence. Costs are cut, and efficiency increases across the whole chain. As a result, companies can earn increased profits while also passing some savings to consumers to increase market competitiveness.

Refer to: Why Do Vape Pens Clog? How to Effectively Unclog the Cannabis Vape?

Providing Value to Consumers and Building Consumer Confidence

The advantages of the Oil IsolationTM Technology extend through the consumer use cycle. The system’s 99% leakage reduction improves the device’s efficiency, ensuring that no oil is wasted. Moreover, the reduction in leaking enhances the device’s longevity, as it will not become clogged and blemished as oil leaks through the device. This improvement in longevity extends to the ability to withstand extreme temperatures. Many consumers emphasize portability in their devices. These consumers can have confidence that their Cilicon device will remain stable through any conditions they may come across.

Experience the benefits of the Oil IsolationTM System with the Following Product Lines:

Elevate S2 Cartridge

Mash Y Cartridge